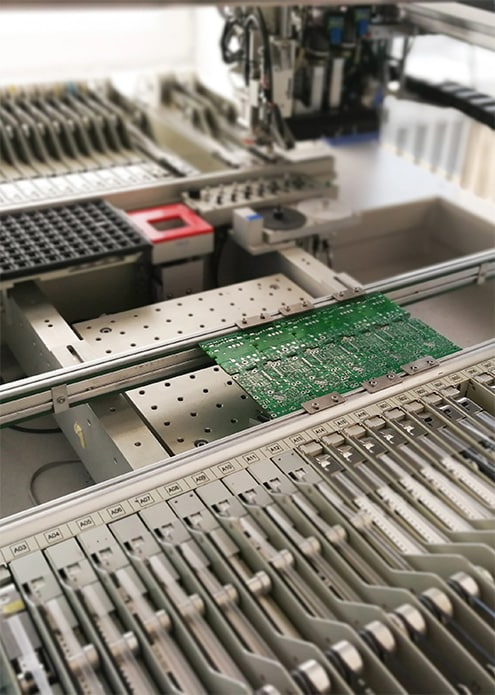

The LRC company is a technological manufacture with a powerful base, including CNC equipment: an automatic line for the installation of SMD electronic components; metal laser cutting machine; sheet bending machine, equipment for winding transformers.

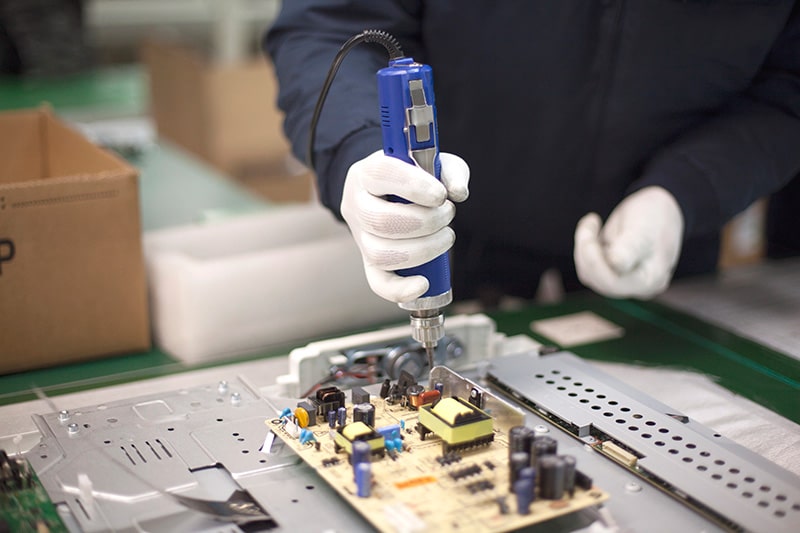

The company has established technologies for the production of lighting fixtures and lamps, transformers, soldering of LED modules and power supplies, metalworking and laser welding, sealing of electronic boards. Together with the department for the development of electronic devices and lighting equipment, the experimental site, the production capabilities of luminaires, lamps and LED drivers are increased many times over, and the quality and reliability of the products are high.

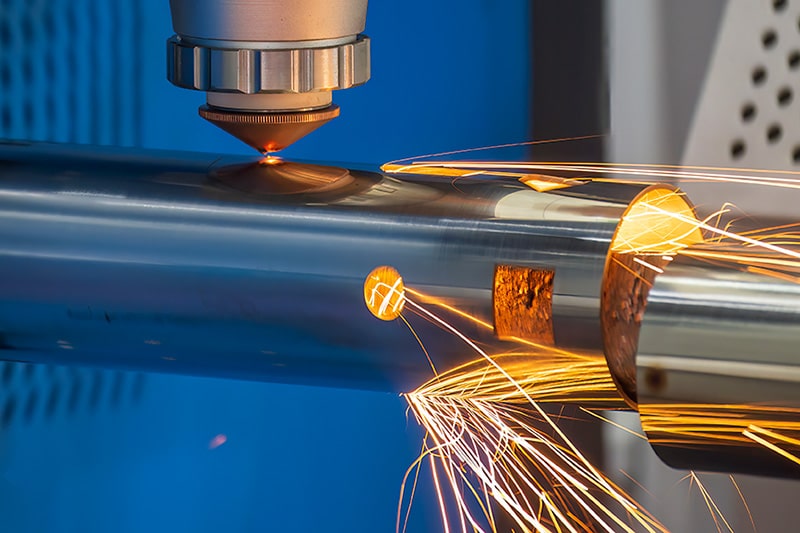

Our production is constantly expanding, in 2023, a new metalworking workshop was launched, equipped with modern CNC equipment. Continuous improvement, modernization, automation of processes to increase efficiency.

Our goal is perfect continuous mass production of quality products: LED lamps and luminaires; drivers and power supplies; LED modules and boards; components and materials for LED lighting.

Currently available production areas: installation of DIP and SMD components; winding products; quality control and sealing of power supplies ensure a monthly production capacity of up to 8,000 power supplies. The manufactured power supplies, LED drivers and LED modules are widely used in lamps from leading domestic and foreign manufacturers, and also allow the company to produce its own line of lamps and luminaires under the LRC brand.

The new metalworking shop allows us to significantly speed up the production process of LRC lamps and improve the quality of metal parts of our lamps and other devices. Now we can control the production process more deeply, including all stages of laser cutting, bending, welding, and powder coating of metal.

LRC is a leading Ukrainian LED lamps and power supplies manufacturer.

LRC is a full production cycle of drivers and power supplies for LEDs, LED modules, luminaires, fixtures, lamps, spotlights and other lighting equipment, as well as electronic devices.

LRC’s production capacity is now complemented by a modern metalworking workshop in the village Budenets, Chernivtsi region, where technological processes for laser cutting of metals, laser welding of metals, bending of sheet metal, and powder coating of metal products have been established. A special feature of our laser cutting complex is the ability to cut pipes with a laser, the maximum permissible diameter of a round pipe is 120 mm. We provide metalworking services, laser cutting of sheets and pipes in Chernivtsi and other cities of Ukraine. We work according to the customer’s CAD files, or our designers will help create a 3D model of the product, and technologists and operators will ensure the production of a batch of products with accuracy, high quality and on time. To order laser cutting and welding, bending, and coating services for metal, please contact us by phone numbers listed below.

LRC contract manufacturing offers a full range of services in the field of design, development, DIP and SMD mounting of components on printed circuit boards, programming of electronic device controllers. Based on the technical specifications, we develop a prototype and test the device; after agreement with the customer, we prepare a schematic diagram of the device and the corresponding documentation. This is followed by ordering a trial batch of printed circuit boards, installation of the device, testing, and preparation of technical production documentation. At the request of the customer, we can begin mass production of electronic devices after previously agreeing with him all stages of production: the configuration and price of the product; installation features and quality control; payment and lead time.

Enter your intention of the phone and email and our consultants will contact you.

Please share your impressions about our company. Customer reviews will help us to become better.